Volpak Intralogistics Project: future-proofing Lean Manufacturing

Companies often face operational challenges that hinder performance and increase costs: limited warehouse space creates bottlenecks, while long, complex, and inflexible production processes reduce their ability to adapt to changing demand. Rising fixed costs add further pressure, and frequent weekly or even daily picking activities place an additional burden on operations. These issues lead to delays, inefficiencies, and higher overall expenses.

The Volpak Intralogistics Project, focused on Lean Manufacturing, helps address these problems by streamlining workflows, improving responsiveness, and enhancing productivity across the entire production system.

A customer-oriented, fully automated intralogistics system

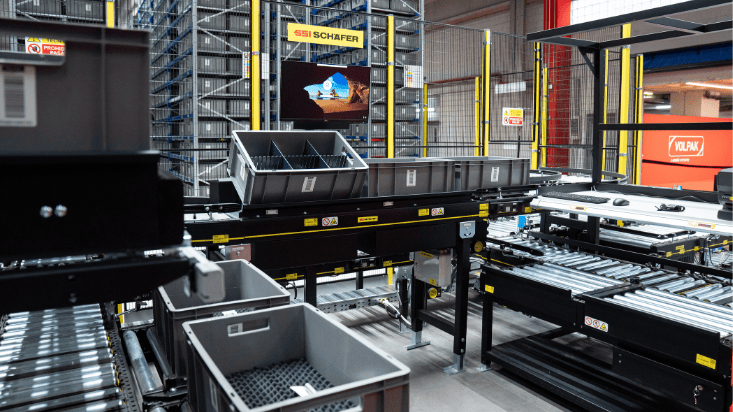

The Volpak Intralogistics Project introduces a fully automated, pull-based warehouse system connected to production and assembly lines, integrating Lean principles such as Just-in-Time (JIT), one-piece-flow, and waste reduction, to ensure parts are delivered exactly when needed, maximizing efficiency and minimizing costs. In fact, automation provides fast, and accurate handling of materials to ensure that parts flow smoothly to the production line at the right moment, improving efficiency, reducing inventory, and preventing bottlenecks.

Volpak innovative intralogistics systems optimize the production from different points of view, starting from materials reception: orders arrive at any time, and the system collects requests automatically. Sorting and picking then align with the production demand, with real-time inventory and traceability.

To maximize production efficiency and minimize unnecessary work-in-progress inventory, orders are prepared as late as possible, closely following the weekly assembly plan. This ensures that components and materials are staged only when they are actually required for upcoming production, reducing the risk of overstocking and keeping the process responsive to changes in demand. At the same time, warehouse materials are restocked based on real consumption rather than forecasts: instead of pushing large batches into inventory, replenishment is automatically triggered only when stock is low. This approach allows components to flow smoothly through both the production line and warehouse, minimizing the waste, and maintaining a more predictable, efficient operation.

Finally, implementing a one-piece flow allows each item to move through the production process continuously, ensuring that deliveries are made on time, urgent orders are clearly identified and prioritized within the workflow.

Autonomous Mobile Robot Integration

The integration of Autonomous Mobile Robots (AMR) showcases cutting-edge industrial automation by streamlining the movement of cargo between storage areas and operators. By automating these internal logistics tasks, warehouses can achieve higher efficiency and reduce manual handling, to lower the risk of potential mistakes. The system also allows for an optimized layout, accommodating boxes, pallets, lifts, and long, enhancing overall productivity.

Warehouse Management System at its finest

The system backbone relies on a Warehouse Management System (WMS) fully integrated with SAP to enable seamless data management across all warehouse and production operations. This integration ensures that information on inventory, orders, and material movements flows automatically between systems, eliminating manual entry errors, and providing real-time visibility.

By connecting the WMS with SAP, the company can optimize stock levels, streamline processes, and make faster, more accurate decisions. In essence, this setup creates a unified digital infrastructure that supports efficient operations, enhances traceability, and allows the entire supply chain to function smoothly.

Investing in the future

Volpak is making significant investments in advanced automation technologies to better prepare for and anticipate future market demands, ensuring the company can respond quickly to evolving customer needs.

At the same time, these efforts aim to set new industry benchmarks for efficiency, productivity, and innovation, positioning Volpak as a leader in adopting cutting-edge solutions and driving operational excellence in manufacturing innovation.