Volpak & Coesia at Pack-Expo 2022: the future of automation starts in Chicago

Coesia, a group of 21 companies specializing in innovative industrial and packaging solutions presents at the Pack-Expo (Booth 2501-South Hall), machines and products designed to increase the reliability and efficiency of production processes in three areas dedicated to Food & Beverage, Pharma & Personal Care and Cross Industry Automation. Coesia is also launching the Re-commerce project dedicated to companies looking for automated online order management solutions.

Coesia presents, at the 2022 edition of Pack-Expo, the Group's solutions aimed at automating manual operations within the production plants: from the unloading and handling of raw materials to primary packaging and from secondary packaging to end of line. The goal is to use highly efficient and reliable machinery to make processes autonomous, especially with regard to the most repetitive tasks, reserving higher added value activities for employees.

At Pack-Expo, the reference fair for North America dedicated to the process and packaging industry, Coesia is launching the Re-commerce project. With its expertise in the world of automation, the Group proposes itself as a solid partner for those companies looking for automatic solutions for the management of orders from online channels. From robotics to fulfillment solutions to box-on-demand, from mass-customization to sorting systems, there are many skills made available to customers in the e-commerce world, with solutions that focus on agility, flexibility, and efficiency.

Hand in hand with automation, Coesia also continues to invest in digital tools and services - fundamental pillars of the corporate strategy - to optimize the efficiency of machines, lines, and entire factories, and to enhance its customer service.

On the digital front, Coesia presents its latest portfolio innovations in the Coesia Digital and Customer Service areas at booth 2501 (South Hall).

An area of the booth is dedicated to sustainability, which is confirmed as a pillar of the Group's strategy: the machines on display are able to handle sustainable paper-based materials or single-material plastic films, that are easier to dispose of at the end of use. Furthermore, thanks to the Coesia Shelf of Sustainable Solutions it is possible to experience firsthand more than 50 eco-sustainable packaging solutions for multiple applications, designed by the Coesia companies.

The Coesia booth is divided into three areas where technicians and experts present the Group's solutions: Food & Beverage, Pharma & Personal Care, Cross Industry Automation.

Twelve Group companies are present: ACMA, Atlantic Zeiser, CITUS KALIX, FlexLink, G.D, GF, HAPA, MGS, NORDEN, R.A Jones, Tritron, and VOLPAK.

Food & Beverage

- ACMA, a leading company in the production of packaging machines in the consumer goods market with almost 100 years of experience, participates with the CW 800, a wrapping machine for rounded chocolate pralines. The model is characterized by flexibility, managing two different wrapping styles - double twist and rolled aluminum - with a quick change of format and wrapping style. The machine is characterized by gentle handling of the product and excellent wrapping quality even at high speed, with the ability to handle different wrapping materials, including mono-materials and paper-based ones. In addition, it features a laser marker, which allows inserting alphanumeric strings on the primary packaging such as the expiration date of the products.

- R.A.Jones showcases the new patent-pending multipacker speed-up kit on the Meridian XR MPS-300, its most popular multipacker solution for canned food and beverages. The new speed-up kit technology - applied to the machine - makes the multipacker the fastest on the market, sustaining speeds of 345 cartons per minute for 4, 6, and 8 pack configurations. The new technology can be retrofitted to existing Meridian XR machines already installed or on new equipment orders. A testament to the longevity of its packaging machinery, R.A Jones also exhibits two machines during the Pack to the Future exhibition, which celebrates the history of the packaging industry. This includes a 1930s soap press and a 1922 crayon cartoner celebrating its 100th anniversary, which will be running, demonstrating the quality of the packaging equipment that R.A Jones is known for throughout the industry.

Pharma & Personal Care

- CITUS KALIX is present with the KP 600 EVO, the 60 ppm cartoning machine, and the KX1103 EVO, the 110 ppm tube filling machine for applications in the health and beauty sector - both belonging to the family of “evolved” EVO solutions. With the EVO generation of Citus Kalix, changing formats has never been easier. The procedure, simple and fast, can be performed by operators of any skill level. Disassembly of the format parts does not require any tools and the full changeover can be done in less than 10 minutes. The main automatic settings are performed by a servomotor and an automatic counter, driven directly by a new HMI.

- HAPA introduces the new H382 Hybrid printing system that combines Flexo and Digital printing technologies and, for the first time, unites cutting-edge smart factory and camera inspection functions. This latest evolution of the Hybrid technology, whose predecessor is considered the global standard for inline blister foil printing, enables a digital transformation of the graphics chain from PDF to package. By offering printing and inspection in a pre-validated package that shares the same "one pdf" workflow, the H382 minimizes project validation, implementation efforts and risks while reducing installation and commisioning times. Thanks to the award-winning OptiMate HMI, the H382 also sets the benchmark in terms of ease of use. Several new design features help to further optimize maintainability and service.

- NORDEN, a leading company in the supply of high-performance systems for tube filling and cartoning, presents an integrated line that includes the NM 702, the 80 ppm tube filling machine equipped with the proven NORDEN oval racetrack and 22-tube holders as standard. At the booth there is also the NTP 80 machine for packaging tubes in trays and boxes, capable of managing different types of packaging, with extremely simple and rapid format changes.

- With the aim of providing added value to customers and creating synergy with all the companies of the Group, the Pharma & Personal Care area are also present the experts of G.D, a world leader in high-tech machinery for the tobacco and special products industry and GF, a supplier of turnkey solutions for the pharmaceutical industry, in particular for the primary packaging, filling and inspection of injectable drugs, as well as for the aseptic process of liquids or powders, in vials, ampoules, cartridges or syringes, including mechanical and robotic applications.

Cross Industry Automation

- MGS uses the prestigious PackExpo 2022 showcase to launch the TLCP-20, the latest innovation in the field of high-performance secondary packaging. Based on MGS's proven cartoning technologies, the TLCP-20 is a versatile Top Load Case Packer that can be customized to handle complex pack patterns. Responding to customer demands for a flexible, space-saving solution, the TLCP-20 is also equipped with the Illumaguard® monitoring system as well as a content sensitive HMI message display that will improve packaging line efficiency, increase packaging numbers production and reduce costs. Reaching speeds of up to 20 cartons per minute, the TLCP-20 more than doubles the speed of the other case packers offered by MGS.

- FlexLink offers automated solutions for production flows that contribute to sustainable manufacturing. Thanks to the technicians present on the Coesia booth, it is possible to attend a live demonstration of the industrial robot palletizer RI20 and the collaborative robot palletizer RC10, integrated with the WLX stainless steel conveyor. Both palletizing solutions make production planning more flexible, as they are mobile, very compact, easy to assemble and install and quick to relocate when needed. The WLX conveyor is a hygienic, stainless-steel conveyor used for food and other applications that require high hygiene requirements. It is designed to ensure safe and clean transportation of products and complies with 3A and EHEDG standards.

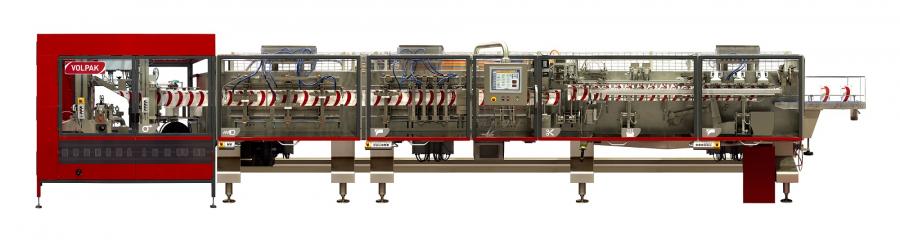

- VOLPAK maintains its commitment to sustainability by exhibiting the SI 280 machine at Pack Expo 2022, capable of handling 100% recyclable materials (both packaging material and the hinge of zip pouches). Assisted automated format change is presented on the SI 280 - a feature now available for the entire SI series via HMI. Format change is an important phase of production, which is why VOLPAK has automated some steps, especially in the envelope forming area, to optimize and speed up operations, allowing even technicians without specific training to be able to work on the machines. The automation and digitalization of the entire SI series allow VOLPAK machines to be increasingly interconnected with production processes.

- With decades of proven experience in inline printing, Atlantic Zeiser introduces a new system for direct printing of flexible narrow web materials, the DIGILINE Vario. This solution allows taking advantage of the benefits of just-in-time printing and late-stage customization for packaging web-based packaging formats. With an end-to-end digitized workflow for printing and inspection, the DIGILINE Vario is designed to deliver flexibility and agility to packaging operations, radically reducing time-to-market.

- Alongside Atlantic Zeiser is TRITRON, a company specializing in the development and production of inkjet inks and ink accessories for impact-free printing technologies (NIP). TRITRON provides multiple digital ink solutions, from established UV/UV LED inkjet inks that are suitable for flat, flexible, rigid, or cylindrical bodies, to the wide range of TIJ 2.5 inks. Moreover, TRITRON offers ecological water-based inkjet inks and, through close collaboration with HAPA and Atlantic Zeiser, the companies are able to offer water-based digital printing solutions making the future of personalized packaging more sustainable.

At the booth area dedicated to Coesia Digital:

- OptiMate, Coesia proprietary smart HMI developed to accelerate operations such as format change, troubleshooting, maintenance, or training of technicians and to facilitate access to guided procedures and digital documentation directly on the machine. OptiMate is visible and testable on the solutions of ACMA, Atlantic Zeiser, CITUS KALIX, HAPA and VOLPAK, and Enflex, a brand of VOLPAK, as well as within the Coesia Digital corner.

- PerforMate, Coesia's IIoT platform for real-time machine monitoring allows to improve the control, collaboration, and performance of the entire machine pool, also working as a single portal for many innovative services. PerforMate is visible on CITUS KALIX, MGS, NORDEN, R.A Jones, and VOLPAK solutions.

- UltiMate,the advanced software platform for analysis, artificial intelligence and machine learning. Directly connected to the other Coesia Digital services, this platform has been designed to enhance productivity and quality, without losing sight of maintenance and cost containment. UltiMate is present in the Coesia Digital area.

- HyperMate, an end-to-end solution for Manufacturing Operations Management designed to achieve complete digitalization of production processes. Thanks to its ability to adapt to customer processes, HyperMate promotes automation and improves the quality of operations by scaling the automation model of the machine to the factory level. HyperMate is also present in the Coesia Digital area.

At the booth area dedicated to Customer Service:

- Webshop, the Coesia online platform to manage and monitor spare parts orders quickly and efficiently. The clear interface, the photographic catalog, and the possibility to search and select components in different ways (e.g. upload of lists) make the Coesia webshop extremely intuitive.

- Remote Assistance, includes assistance activities that do not require the physical presence of a Coesia operator on board the machine. Thanks to advanced remote connectivity and collaboration tools, video, and augmented reality, Coesia is able to provide remote technical support and diagnosis in real-time.

- Service Agreement, a suite of structured services that can be customized according to customer needs with the aim of optimizing machinery maintenance, ensuring the best possible conditions of use and maximum productivity. This suite ranges from simple scheduled maintenance to the most complex full-service contract with guaranteed performance, combining different service elements.

- OEE Consulting, a specialized consultancy service, which, starting from an assessment of the efficiency level of the customers' operations where Coesia machinery is installed, aims to identify and implement solutions that improve their performance.

Coesia is a group of 21 companies specializing in highly innovative industrial and packaging solutions based in Bologna, Italy. Coesia companies are leaders in the fields of advanced automatic machines, packaging materials, industrial process solutions, and precision gears. Coesia's customers operate in a wide range of industries such as aerospace, ceramics, pharmaceuticals, electronics, healthcare, automotive, tobacco, consumer, and luxury goods.