The next generation of Factory Acceptance Testing: the Live Remote FAT

One of the most crucial milestones of every machine purchase is what is known as the Factory Acceptance Test (FAT). The purpose of the FAT is always to demonstrate whether a machine is operating according to mutual contractual agreements and identify any inconsistencies with the original specifications and the performance of the machine before shipping to the buyer’s location.

As the name implies, FATs are always performed in the manufacturer’s factory. For this reason, a small team from the buyer’s factory traditionally makes the trip in order to witness the FAT formally. While these “face-to-face” meetings have been the standard approach to performing a FAT, an increase in global legal travel restrictions as a result of the global COVID-19 crisis has made this important step in the buying process more difficult. Even where travel restrictions have been eased, extended quarantine regulations and other such complications make traveling more difficult than in the past.

Aside from these global travel restrictions, many companies in the flexible packaging industry would need and prefer to cut down on expenditures such as personnel travel and the related costs, from the round trip through to accommodation and subsistence coverage. As flexible packaging companies’ inclination to travel becomes more complicated and less immediate, there is an increasingly greater call for advanced technological solutions that can assure the same integrity and truthfulness as an in-person FAT.

THE NEXT GENERATION: VOLPAK'S LIVE REMOTE FAT

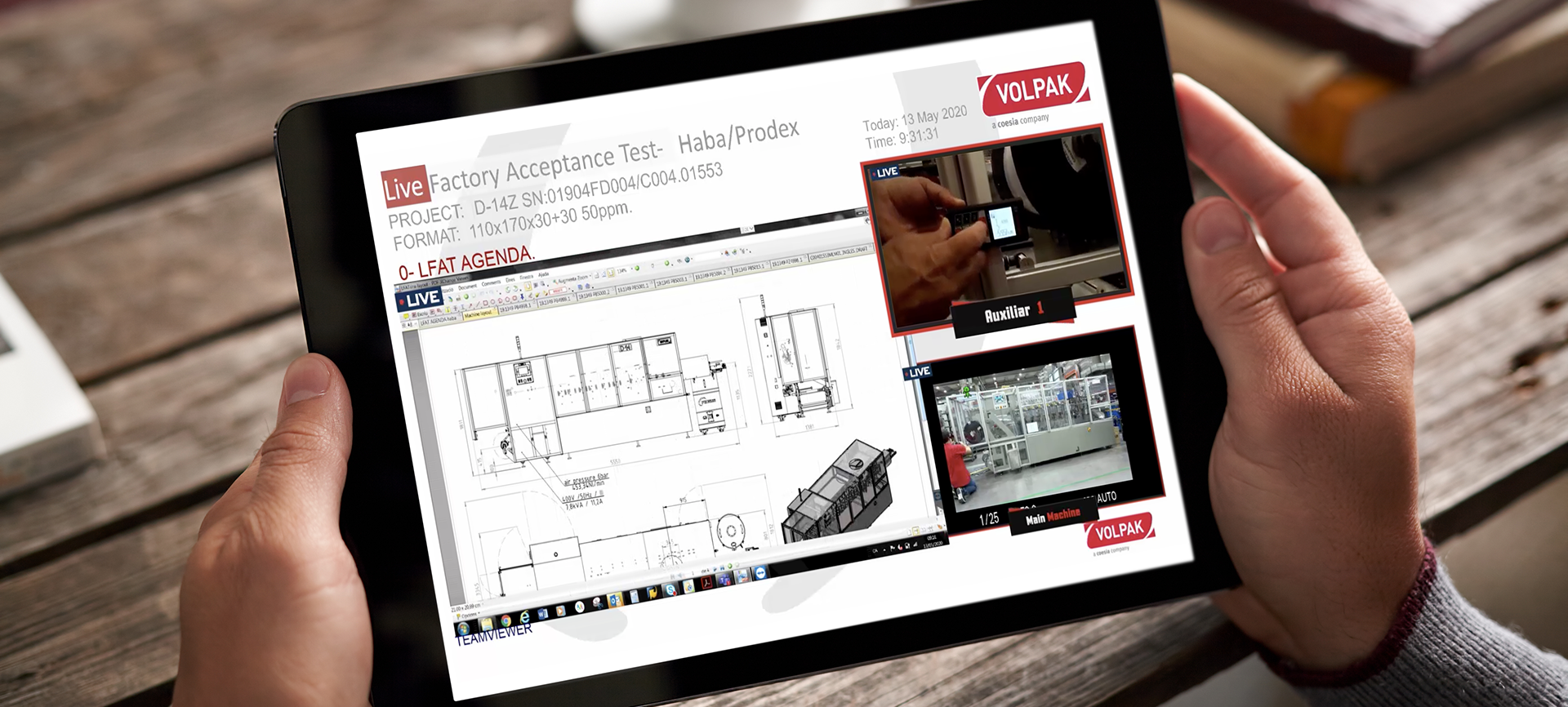

In response to the needs of clients who are unable to go on a trip or wish to cut down on travel expenses, Volpak has introduced the latest machine testing tool, known as the "live remote FAT" or Live R-FAT system. In fact, the Live R-FAT works using the same system as the FAT, except that it offers a unique opportunity for customers from any location in the world to witness the process directly from their physically remote distance.

The way in which the virtual Live R-FAT works is by setting up cameras around the machine that is being tested in the manufacturing area of the Volpak factory in Santa Perpetua, Barcelona. The live stream is managed by Volpak’s technical specialists through the control desk. It also provides access to a live chat which allows the manufacturer’s engineers to interact with the customer team in real time.

Depending on the machine, the live recording system includes 4 to 7 cameras working simultaneously, as well as other remote tools monitoring electronic devices such as HMI, to allow the client to witness each and every step of the Live R-FAT in real-time. The steps focus on checking machine characteristics such as dimensions, finishes, wiring and connections, security and alarms, machine performance with the product, packaging material, pouch style and size, and checking pouch quality, resistance, tightness, finishes, etc.

Other specific checks of flexible packaging machines include:

- Physical check of items purchased under contract

- Machine measurements

- Operational tests

- Multiple formats check and run

- Pouch leakage

- Macro Sealing quality

- Empty pouches

- Pouch dimensions

- E-stop and guards check.

It becomes possible to check for completeness across the board. In addition to assessing the full functionality of a machine, during the v process, all of the technical documents are also verified, and a thorough final inspection is carried out of all of the equipment. Interaction is made possible through a handheld camera in addition to the live chat.

The best part is that the Live R-FAT is completely convenient and does not require the customer to purchase any additional technology, since it is both “multi-platform” and “multi-operating”. The entire Live R-FAT process is viewable in real-time through any videoconferencing software of your choice, like Microsoft Teams, Skype, Zoom, Google Meet, Cisco Webex, etc. into a private interactive conference.

THE REMOTE FUTURE OF FACTORY ACCEPTANCE TESTS

Thanks to the live remote FAT, or Live R-FAT, customers can save even more time, money and resources than before. All of the live remote monitoring tests conducted by Volpak have been a great success so far, confirmed by 100% of the satisfied clients who have already benefited from this technology during the travel restrictions imposed by the COVID-19 pandemic that took over the first part of 2020.

Remote observation provides transparency and reliability through the manufacturing and testing processes. As an additional perk, unlike the traditional FAT where normally only 2-3 people travel to validate the machine, all customer employees including all engineers and machine operators can participate in the new Live R-FAT.

As the world continues to adapt to changes that affect travel and movement, Volpak recognizes the need to implement solutions that ensure the same level of accountability, trust and communication as ever. Email us today to find out about how we can discuss live remote factory acceptance testing of your Volpak machine.